We welcome any request for the environmental technological process. We promise timely delivery of the best possible solution.

Technology that works

At the heart of the sludge drying system is proven HOLO-SCRU® screw type heat exchanger technology. Screw type heat exchangers have been used in bulk processing for the agriculture, chemical, construction, and food industries for over 70 years. This versatile system is capable of processing everything from apples to zinc. Both reliable and customizable, HOLO-SCRU® equipment is the world standard in indirect screw type heat exchange equipment.

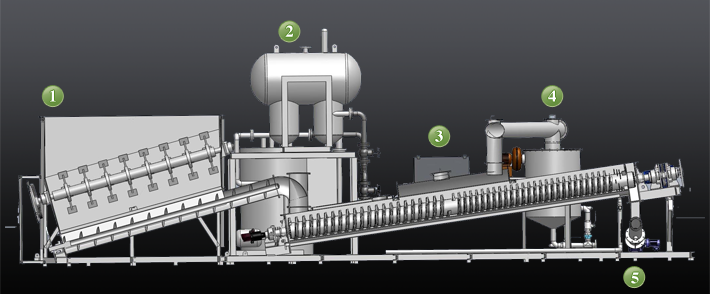

Discover the Bio-Scru system

1. FEED HOPPER

The feed hopper includes twin intermeshed paddle mixers to keep the biosolids homogenized and break up bridging. This feature insures a consistent feed rate and material uniformity. A screw auger located in the bottom of the feed hopper conveys the biosolids to the dryer.

2. THERMAL FLUID HEATER

The thermal oil heater uses PLC control for optimal heating efficiency. The heating can be accomplished with a variety of energy sources including waste heat, solar thermal, bio-gas, natural gas, propane, #2 fuel oil, diesel, coal, or electricity.

3. BIO-SCRU DRYER

The dryer chamber includes twin intermeshed HOLO-SCRU® rotors. In the drying chamber, biosolids are indirectly heated under slight negative pressure in a sealed, anaerobic environment. Thermal fluid is circulated throughout the HOLO-SCRU® rotor and outer jacket of the drying chamber.

4. SCRUBBER/CONDENSER

The condenser system provides the continuous removal of moisture evaporating from the biosolids. The process captures particulate and condenses the evaporated water.

5. COOLING SCREW

The water-cooled screw rotor and jacketed housing combine to cool the dried biosolids for safe handling.

Optimum volumetric reduction and efficiency

Through proprietary design, the BIO-SCRU® dryer reduces biosolid volume by decreasing capacity, or pitch, at each stage of the rotor. This increases loading capacity and utilizes the maximum amount of heat transfer surface (A) through the length of the dryer. Biosolids are accumulated between each stage of the rotor in no-pitch zones allowing the mixing blades to homogenize particle size. The rotor flights use wipers to remove material adhering to the opposing screw. The self-clearing design of the rotors insures that heat transfer surfaces remain free of build-up.