We welcome any request for the environmental technological process. We promise timely delivery of the best possible solution

Robotic Tank Cannon

The Robotic Tank Cannon is a hydraulically operated machine powered by MegaMacs' hydraulic plant. This machine uses water or cutter stock as liquefier to dilute and suspend sludge in tanks (under pressure 20 Bar). The Robotic Tank Cannon is a remotely controlled, high volume jetting system used for cleaning large storage tanks. It works on a process known as hydraulic mining, in which a concentrated stream of liquid such as water is used to dislodge and move sediments. Once positioned inside the tank to be cleaned the cannon's powerful jet can be remotely directed by an operator stationed outside the tank.

A duplicate of the cannon' drive system on the console mimics for the operator, using visual indication, the cannon's nozzle position and elevation allowing the operator to dislodge and slurry the sludge for pumping from the tank for further processing.

Sludge Extractor

The apparatus is used for extraction of sludge from tank interiors and is hydraulically powered by MegaMacs. The Extractor is designed to be easily disassembled into manageable pieces that can be passed through the manhole of a storage tank's exterior for re-assembling inside the tank. Two independently powered track drives are used to propel and maneuver the unit around the tank's interior.

A powerful hydraulically driven digging arm excavates the sludge and draws it into the machine intake where it is slurried with water or oil prior to being pumped from the tank by the onboard pump. When properly operated, the Extractor can excavate, slurry, and discharge from the tank's exterior approximately 18 tons of sludge an hour. A single operator is required inside the tank, minimizing liability.

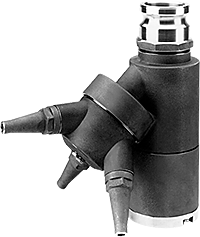

Booster Pump

The submersible booster pump is a small, lightweight portable pump that is used for the transfer of solid laden liquids from storage tanks and sludge lagoons. It is primarily used in conjunction with a liquid jetting device to extract and return liquids and solids to the cleaning system for separation, reclamation, and reuse. Threaded suction ports allow for multiple pumps to be run in series to pump liquids over longer distances. The pump's hydraulic drive allows it to be fully submerged in the liquid being pumped without fear of damaging the drive motor.

Sludge Pump

The sludge pump is specifically designed for heavy sludge. This submersible Positive Displacement Pump can pump substances from water to the heaviest sludge. The pump has a production capacity up to 20 cubic meters per house, which is easily controlled by hydraulic system. Pump construction prevents emulsification which is very important for future sludge processing.

The sludge pump is specifically designed for heavy sludge. This submersible Positive Displacement Pump can pump substances from water to the heaviest sludge. The pump has a production capacity up to 20 cubic meters per house, which is easily controlled by hydraulic system. Pump construction prevents emulsification which is very important for future sludge processing.

The pump is operated hydraulically and extremely safe. Intake is equipped with special knife which cuts ropes, plastic and other small debris. Should sludge be excessive, the pump is equipped with water/steam intakes to dilute sludge on pump exit. The pump has a reverse spin for fast cleaning and is made out of stainless steel and a special aluminum composite for acidic substances. The pump is able to handle debris up to 30 mm.

Washead With Tripod Unit

The 180 - 360 washead with tripod is used for de-sludging and cleaning of storage tanks. This directional tank cleaning machine utilizes three powerful synchronized jets that revolve around the horizontal axis of the machine and index both the bottom and walls of the tank. This indexing provides an extremely tight, half sphere ball and twine pattern that impinges evenly and with great force upon the surfaces being cleaned, providing maximum surface coverage even at a great distance. Incremental nozzle advancement per revolution allows a complete cleaning cycle with every sixty revolutions of the machine's T housing. The machine is driven by the cleaning solution (water) and requires little or no monitoring during the cleaning cycle. The heavy-duty tripod makes it a highly efficient cleaning machine with a simple to use mounting system allowing fast and easy setup.

The 180 - 360 washead with tripod is used for de-sludging and cleaning of storage tanks. This directional tank cleaning machine utilizes three powerful synchronized jets that revolve around the horizontal axis of the machine and index both the bottom and walls of the tank. This indexing provides an extremely tight, half sphere ball and twine pattern that impinges evenly and with great force upon the surfaces being cleaned, providing maximum surface coverage even at a great distance. Incremental nozzle advancement per revolution allows a complete cleaning cycle with every sixty revolutions of the machine's T housing. The machine is driven by the cleaning solution (water) and requires little or no monitoring during the cleaning cycle. The heavy-duty tripod makes it a highly efficient cleaning machine with a simple to use mounting system allowing fast and easy setup.

Hose and Manifold Package

Hose and Manifold package included in MegaMacs system provides auxiliary equipment connections. Powerful pumps and a hydraulic system allows MegaMacs to be located up to 150 m from the treated object.