We welcome any request for the environmental technological process. We promise timely delivery of the best possible solution

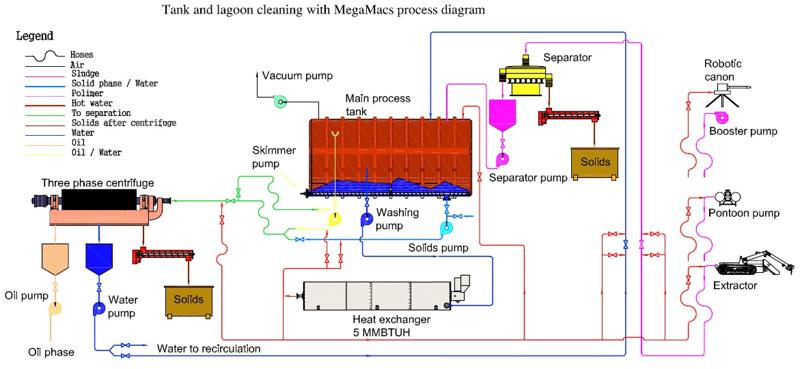

The MegaMacs Process

The cleaning process in general is the same for tank bottoms, processing drummed sludge or cleaning up a lagoon or separator pond. The sludge is liquefied by a washing/diluting agent, extracted from the reservoir and brought to the MegaMacs system.

The main process tank is filled to 80% capacity with water, which is circulated through the heat exchanger and returned to the tank using the wash pump. This re-circulation continues until the solution temperature reaches approximately 180° F (82° C). Subsequently, the wash pump is switched to cleaning mode and delivers cleaning solution into the reservoir to be cleaned. Heated by an on-board heat exchanger, water cuts and dilutes the sludge to a 4:1 creating a mix of oil, water and solids. This mix is then pumped back to MegaMacs up to 500' (150 m) away.

As the mix enters the machine it goes trough the vibrating separator where solids larger than 1/4" (6 mm) are removed and conveyed to the debris box where they are collected for further disposal. The remaining mix of oil, water and fine solids is delivered to the main tank where separation takes place. The majority of solids settle to the bottom of the tank while the water/oil mix (60% oil and 40% water) rises to surface. A floating skimmer pump removes this lighter fraction and evacuates it for further handling. The rest of the liquid is reheated and re-circulated back to the reservoir, closing the loop.

There are two ways to handle this 60% oil and 40% water mix. It may be sold as a final product or directed to the Tri-Phase centrifuge for further separation, to remove fine solids and separate oil and water. As the feed material enters the unit, three separated phases come out from centrifuge.

The oil phase containing at least 95% oil is a sellable product and brings substantial profit.

Depending on peripheral equipment and configuration, the system can process up to 15 tons of sludge per hour.

Different oil products may require specific cleaning solutions (water or cutter stock) which will slightly alter the abovementioned process, creating a different sellable byproduct. Decisions about which solution or equipment to use should be made based on your specific conditions and environment.

MegaMacs will save you time, money and minimize environmental impact of oil tanks and reservoirs cleaning. This is beneficial both for your bottom line and environment!

First Stage

When the sludge level is higher than the manhole, a special bin is installed under the manhole with booster pump placed inside. Manhole bolts are replaced with the telescopic bolts which are slowly unscrewed, allowing a gradual release of sludge from the tank. A booster pump moves the sludge to the MegaMacs Main unit. The hatch is removed and the sludge is liquefied with a pressure handgun. When space is sufficient, the booster pump is moved inside the reservoir and a pressure cannon is installed on the manhole flange. Once there is enough space inside the tank, a robotic cannon is installed and further operations are done remotely.

(Download MegaMacs video - First stage of tank cleaning while sludge level higher manhole.)

Sludge Extractor

The Extractor is a small collapsible scraper used to extract and liquefy sludge from big tanks (over 50,000 cubic meters). It is carried into the tank through the manhole (500 mm) in several light and easy to assemble pieces (the heaviest part is 30 kg). The extractor is re-assembled inside the tank in 2 hours and hydraulically powered by the MegaMacs unit.

Two independently powered track drives are used to propel and maneuver the unit around the tanks interior. A powerful hydraulically driven scraper arm excavates the sludge and draws it into the machine intake; a helical screw moves it to the built-in screw pump where it is slurried with water prior to being pumped from the tank.

When properly operated, the unit can excavate, slurry, and pump up to 15 tons of heaviest sludge per hour. Just one driver/operator is required inside the tank to operate the extractor, limiting liability exposure.